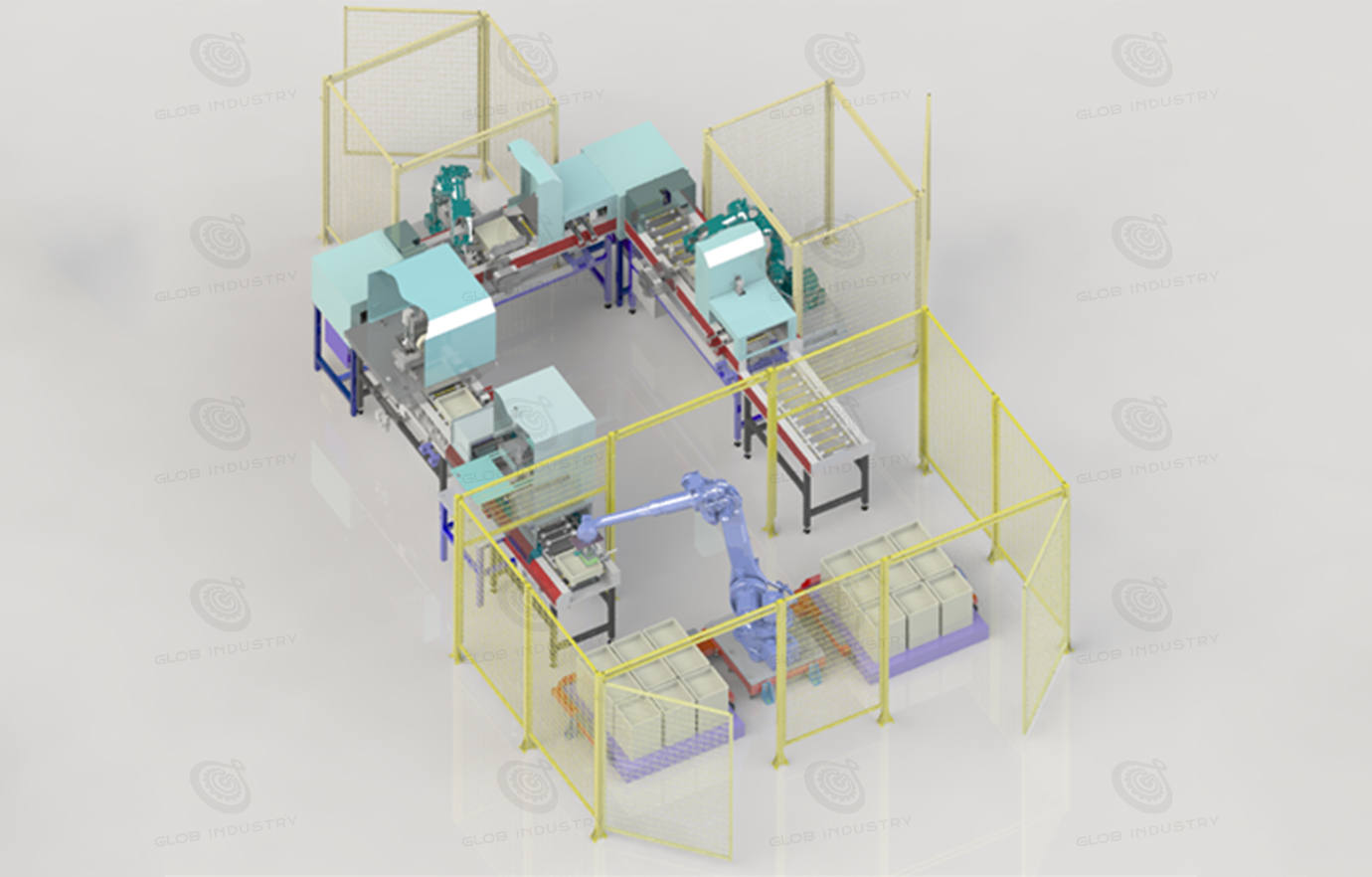

This workstation is used to recycle the cathode materials adhered and corroded in the cathode material sagger of lithium ion battery. The cathode materials rich in cobalt, lithium, nickel and other metals are completely stripped through the flexible cleaning of the inner wall, outer wall, bottom surface and R angle of the sagger, and the by-products are collected for the subsequent fine recycling. While creating economic value, it can reduce the risk of leakage of process formula and transportation of dangerous waste due to the unclean cleaning after the sagger is eliminated.

Full-angle flexible cleaning + negative pressure collection + automatic loading and unloading by robot

One-unit type 300 saggers/day; Double-unit type 600 saggers/day

4.5m*6.5m

Sintering phase of lithium ion battery cathode material