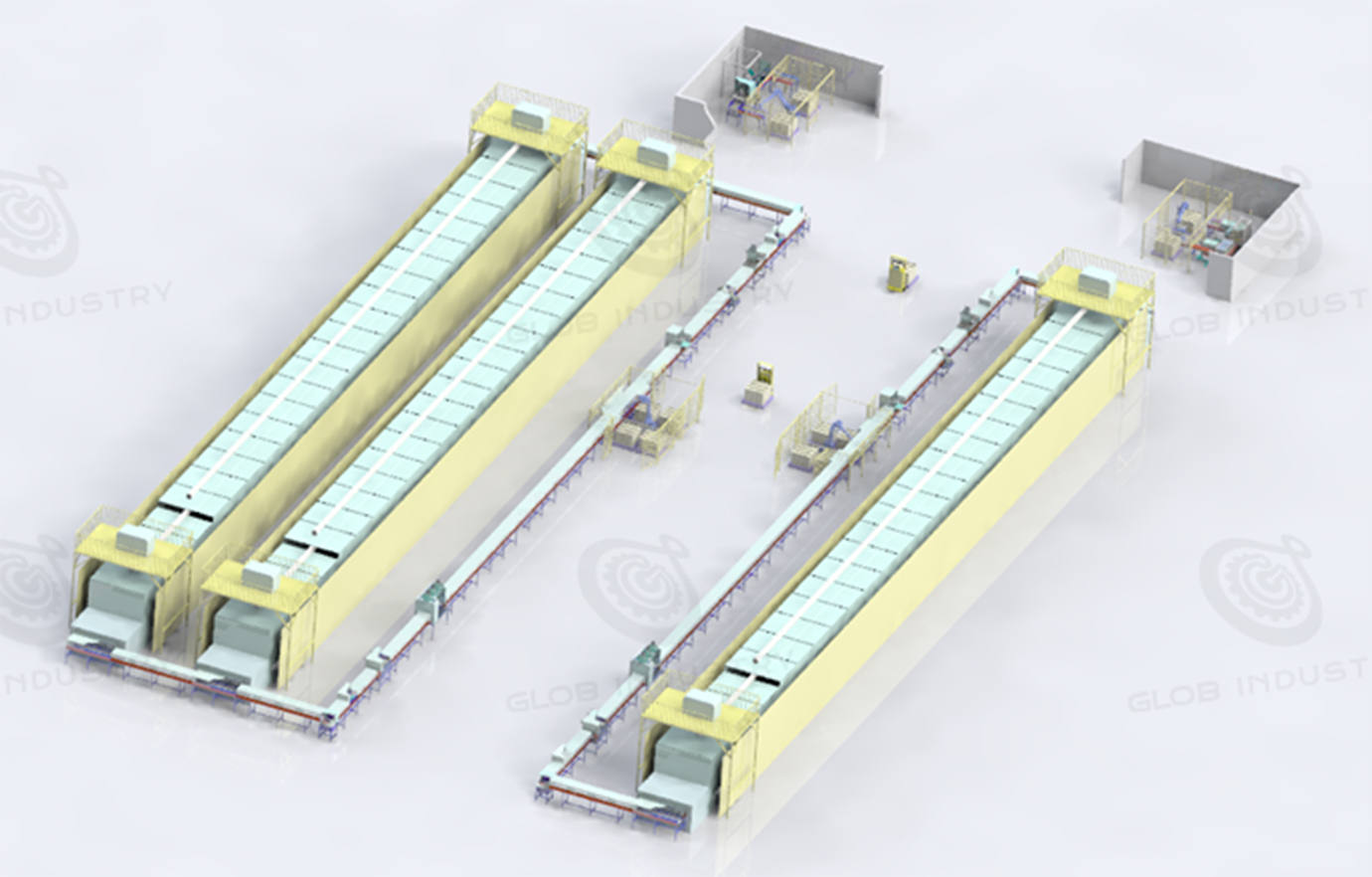

The set of intelligent outer rail line is designed with ultra-high speed moving load, and the maximum efficiency is 180 saggers/hour. Based on the traditional outer rail line, the kiln access, loading sagger, inverted sagger and other high- temperature, high-dust stations are upgraded to avoid the problem of blocking and shutdown due to high temperature and high dust to the maximum extent; Made of integrated high temperature resistant non-metallic material, it can avoid the risk of mixing with foreign metal matters; Combined with the high-precision full-dimension imager to judge the state of the sagger in real time, it can timely remove corroded and ruptured sagger and eliminate the risk of mixing with impurities; The robotic sagger supply system can recover the old sagger materials from time to time, and pre-clean, replace and supplement the newly launched sagger automatically.

Automatic non-metal outer rail line+ robotic sagger supply system + full-dimension imaging detection system + AGV

120-180 saggers/hour

Can be customized according to customers’ requirements

Sintering phase of lithium ion battery positive and negative electrode materials